Best concert ticket sites: your all-access pass to that once-in-a-lifetime experience

Buying Guide Find the best concert tickets at the cheapest prices and get access to rare tickets and more.

Find reviews and recommendations for the latest hobbies.

Buying Guide Find the best concert tickets at the cheapest prices and get access to rare tickets and more.

Buying Guide Take unwanted gift cards and exchange them for cash for a small fee with these websites.

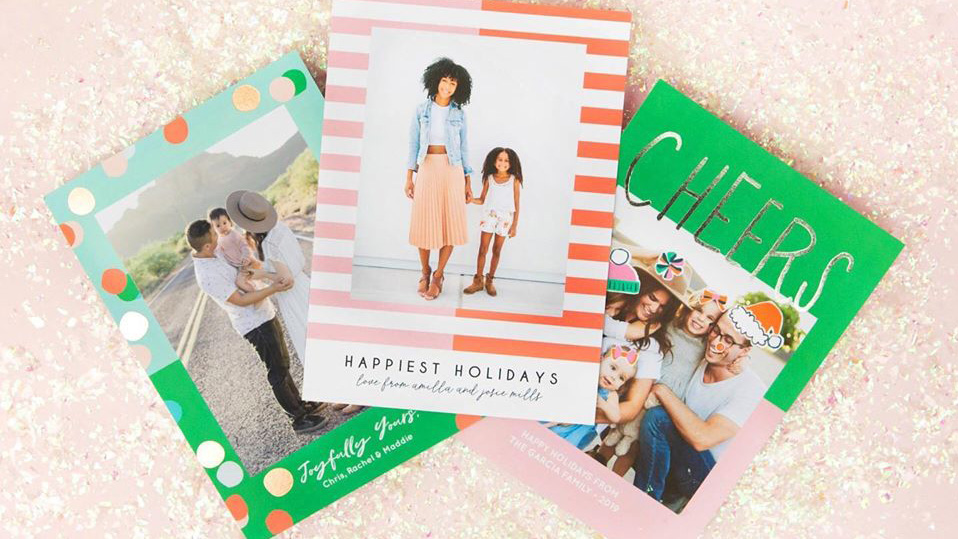

Buying Guide Get the best photo cards for personalized messages that really touch the heart.

Get the best USB microphone for your recording needs, be it vlog, podcast, music and beyond.

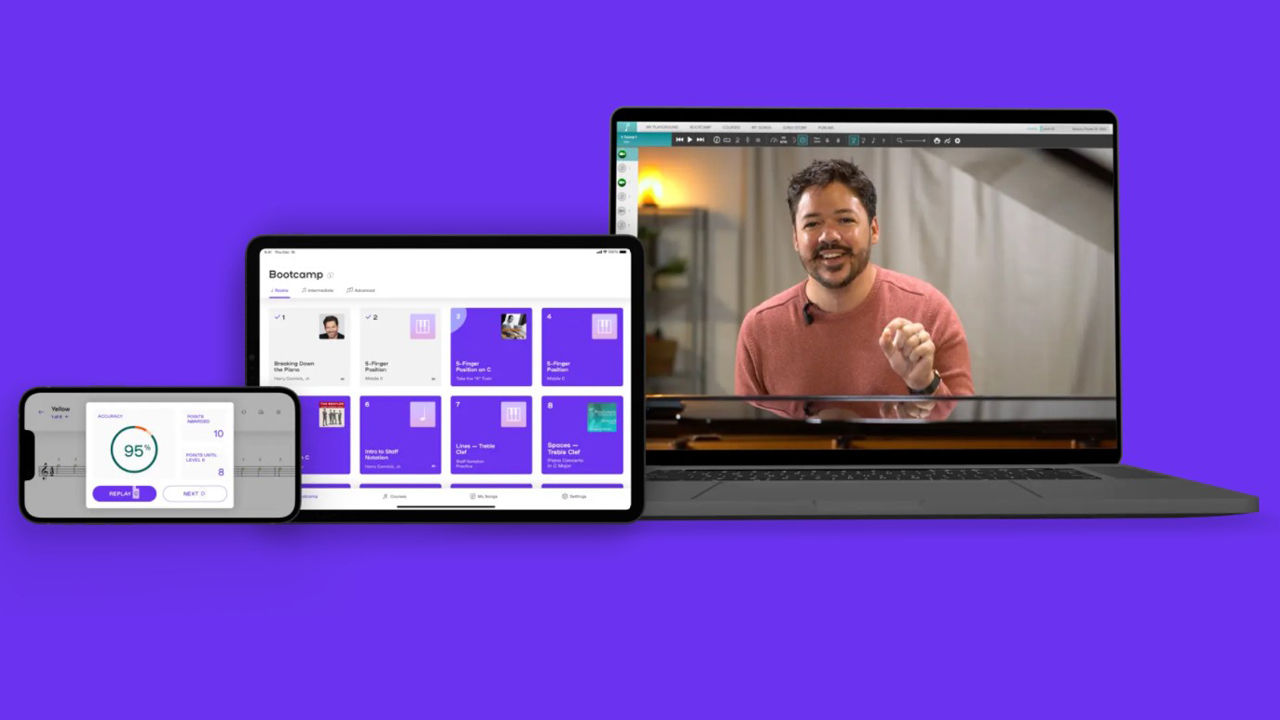

Buying Guide Whether you’re a beginner on the keys, or have years of experience and need a refresher, here are the best online piano lessons to try now

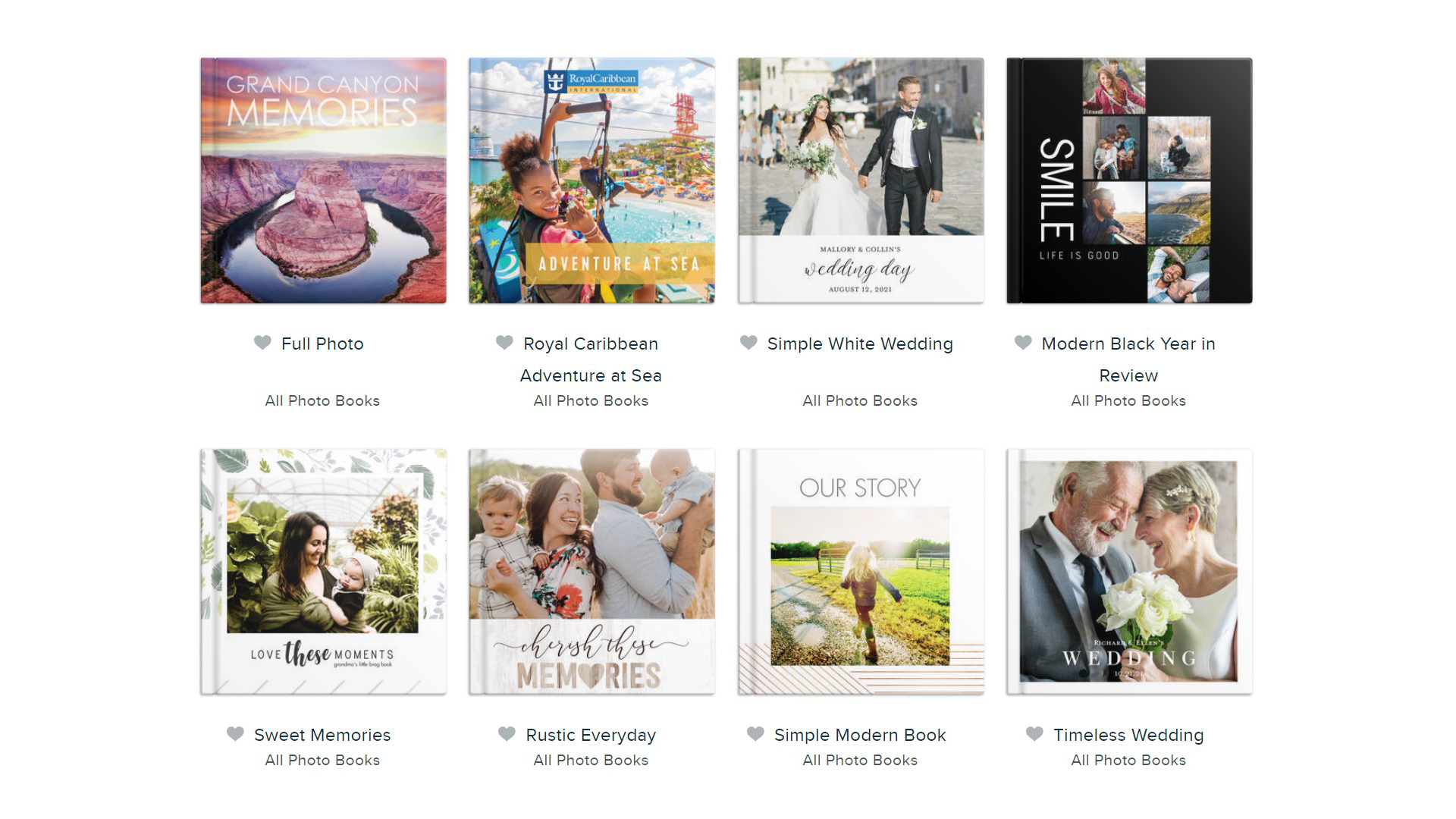

Buying guide The very best photo books you can create from your own photos and order online

Buying Guide We’ve rounded up the best telescopes for beginners, kids and adults who want to get into stargazing.

Review The Bezgar TB141 is a solid and reliable entry-level car that won't set you back too much.

Review The Lionel Polar Express is a fun, easy-to-use train that’s perfect for play or decoration.

The Bachmann Chattanooga is a high-quality train that you can buy for a reasonable price, with lots included in the box.

Review The Lionel Pennsylvania Flyer is a beautifully detailed large train set that's a lot of fun to play with.

Review If it’s still hip to be square, the Canon SELPHY Square QX10 is on trend with its 2.7-inch square print format.

REVIEW Mixbook Photo Cards service strikes a great balance between choice, value, and print quality. It's a great place to shop.

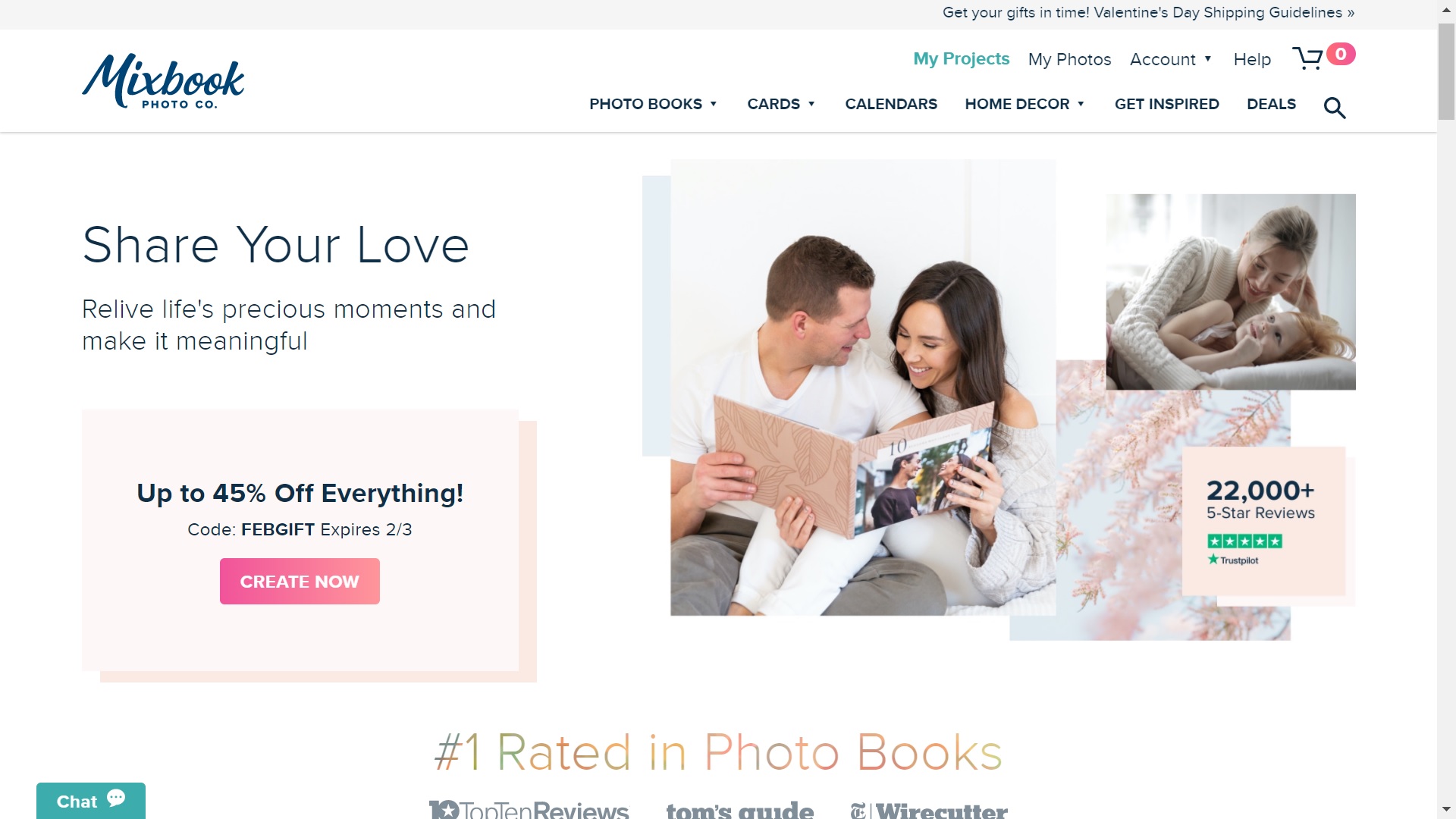

Review Mixbook is a great site for photo gifts, and has a great selection of options for most occasions.